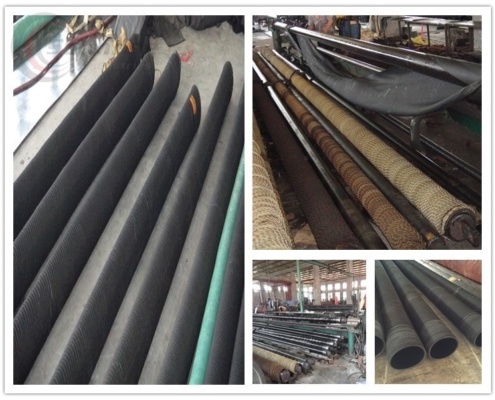

Rubber Suction & Discharge Hose

Rubber Suction & Discharge Hose Hosing are used for vacuum and pressure lines in effluent and industrial applications, water,non-corrosive fluids, and light-duty industrial. Rubber suction and discharge hoses are designed to efficiently transfer fluids from one location to another. They are commonly used in industries such as agriculture, construction, mining, and marine. These hoses offer reliable performance for both suction and discharge applications, making them a versatile solution for fluid transfer.

- Tube: Black NBR rubber, smooth.

- Reinforcement: High strength synthetic cord and steel helix wire.

- Cover: Black wrapped synthetic rubber, abrasion, ozone, and weathering resistance.

- Application: For suction & discharge water,non-corrosive fluids, and light-duty industrial.

- Temp. Range. : – 5 ̊C to +60 ̊C (23°F to 140°F)

Specification of Rubber Suction & Discharge Hose

Rubber suction and discharge hoses possess several important features:

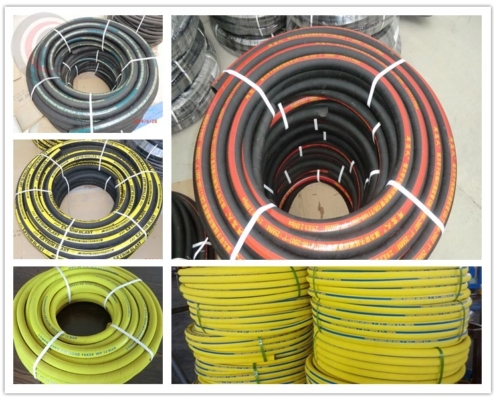

- Versatility: These hoses are suitable for handling a wide range of fluids, including water, slurries, chemicals, and various other materials.

- Flexibility: The rubber construction allows for easy handling, bending, and installation, even in demanding environments.

- Reinforcement: The hoses may include textile or wire helix reinforcement to provide strength and resistance against collapsing or kinking.

- Abrasion Resistance: Rubber suction and discharge hoses are designed to withstand abrasion, ensuring durability in harsh conditions.

- Weather Resistance: These hoses can handle exposure to sunlight, ozone, and extreme weather conditions without deterioration.

- Temperature Range: Depending on the specific hose, they can operate within a broad temperature range, accommodating diverse applications.

- Different Sizes and Lengths: Rubber suction and discharge hoses are available in various sizes and lengths to suit different requirements.

| Part No. | Size | I.D. | Thickness | Length | W.P. | B.P. | Vacuum |

|---|---|---|---|---|---|---|---|

| # | Inch | mm | mm | m/coil | Bar | Bar | Bar |

| SHRS3851 | 1-1/2″ | 38 | 6.5 | 12 | 10 | 30 | -0.85 |

| SHRS5164 | 2″ | 51 | 6.5 | 12 | 10 | 30 | -0.85 |

| SHRS6477 | 2-1/2″ | 64 | 6.5 | 12 | 10 | 30 | -0.85 |

| SHRS7690 | 3″ | 76 | 7 | 10 | 10 | 30 | -0.85 |

| SHRS89104 | 3-1/2″ | 89 | 7.5 | 10 | 10 | 30 | -0.85 |

| SHRS102118 | 4″ | 102 | 8 | 10 | 10 | 30 | -0.85 |

| SHRS127145 | 5″ | 127 | 9 | 10 | 10 | 30 | -0.85 |

| SHRS152170 | 6″ | 152 | 9 | 10 | 10 | 30 | -0.85 |

| SHRS203224 | 8″ | 203 | 10.5 | 10 | 10 | 30 | -0.85 |

| SHRS254276 | 10″ | 254 | 11 | 10 | 10 | 30 | -0.85 |

| SHRS304326 | 12″ | 304 | 11 | 10 | 10 | 30 | -0.85 |

| SHRS350378 | 14″ | 350 | 14 | 10 | 10 | 30 | -0.85 |